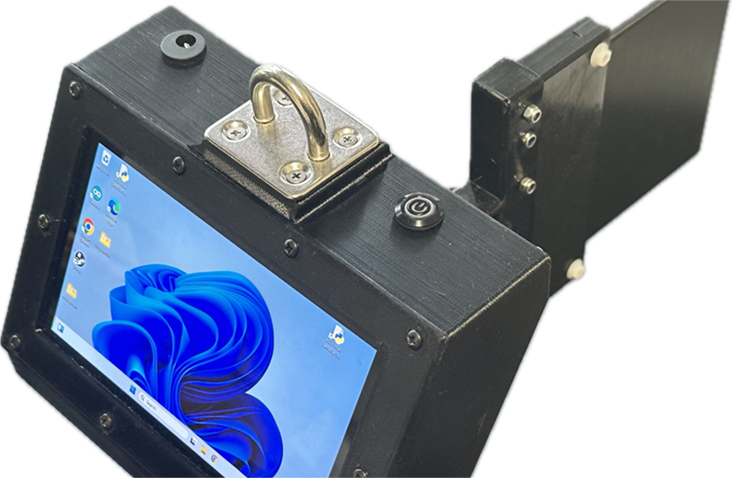

The handheld microwave-based devise helping to non-invasively measure IMF%

The handheld microwave-based devise helping to non-invasively measure IMF%

Carcase grading device set to pave the way for premium lamb brands

A handheld microwave-based device that can non-invasively measure intramuscular fat (IMF%) in lamb carcases has recently achieved AUS-MEAT accreditation – paving the way towards the development of premium lamb brands.

Developed by Murdoch University as part of an MLA Donor Company project that operated in parallel with the Commonwealth-funded ALMTech project, the non-invasive technology was originally designed to measure fat depth in both lamb and beef. However, through using low power non-ionising electromagnetic waves, researchers found the device was also able to measure IMF% in lamb.

Murdoch University Professor Graham Gardner described the development of this device by his meat science research team as an exciting step forward for the sheepmeat industry.

“Our engineers, led by Dr Jayaseelan Marimuthu, have been working tirelessly to deliver the first non-invasive device that can be used on a hot carcase to measure both GR tissue depth and IMF,” he said.

Setting better prices for lamb producers

From a producer perspective, Graham said the key highlight of this new device is its potential to aid in the delivery of fairer and more accurate grading of carcase eating quality.

“Now that the technology is here, there’s an opportunity for the sheepmeat supply chain to take advantage of the information it provides to create premium lamb brands with MSA’s sheep cuts model,” he said.

“This implementation of MSA within sheepmeat supply chains will also allow for the introduction of price incentives for producers delivering those premium lamb cuts.”

According to Graham, this is possible thanks to the accuracy of the device which was confirmed via testing on large volumes of phenotypically diverse lambs at the WA Meat Marketing Co-operative’s (WAMMCO) Katanning abattoir.

“The support we received from the producer-owned co-operative was crucial to a large portion of our lamb research,” Graham said.

“When trialling the device at the co-op, we took not one, but three measurements to ensure it displayed a really good level of repeatability.

“We also used it alongside three other objective measurement microwave devices to confirm across the board accuracy, ensuring they all provided the same reading.”

“Overall, it’s a huge breakthrough that represents an initiative to respond to industry demands to capture value-chain price differentials with objective measurement devices.”

The next steps towards commercialisation

The microwave system has already achieved its first commercial installation at WA’s Dardanup Butchering Company, where the technology is being utilised to measure GR tissue depth in lamb.

Moving forward, Graham said future work will be focused on not only putting this objective measurement capability in the hands of producers to provide data that enables better informed decision-making, but also getting this technology AUS-MEAT accredited for measuring fat depth in beef carcases.